Hmm, well despite the obvious Covid problems I hope we’ve all managed to hang on and find a bit of shooting over the year. Hopefully 2021 will be somewhat better, but probably not until late spring or summer being realistic.

I know that during lockdown some people have been doing more to make their own kit whether it be making strings, arrows, leather work or having a go at making a bow. Learning new skills is a good way to keep mind and brain active and combat the stress, so if you haven’t tried yet, have a go at making a bow or, even just a simple stick and string kid’s bow.For my part I’ve taken up the blues harmonica and got back into playing on-line bridge.

I think I only did two field shoots over the year and some roving.

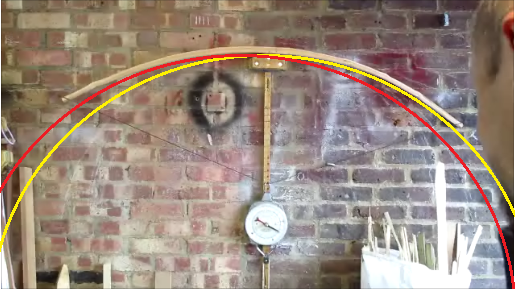

My bow making has been slow and steady, having made about 10 bows. Highlights have been some interesting repair work, cutting some Walnut which will be ready to use in late January, and a few bamboo backed bows, boo/Yew/Lemonwood. A couple of Boo/Yew, an 80# Yew primitive and an Ash backed Yew heavyish flight bow (~80#) that I haven’t really tested.

The Horn bow (horn/wood /sinew Turkish, Ottoman style bow) which I bought as a part finished project was probably the most interesting. The work I’ve done to correct its sideways bend/twist, which became evident after the first session of shooting, has been very successful, although I’ve yet to shoot it since that work.

I also had a quick play with a skinny off-cut of yew to make a small “H bow” flight bow. The wood was knotty and it only survives a couple of shots. It did however allow me to try an extended grip which meant I could use my normal anchor point whilst drawing a 17” draw bow. I may build another version from clean wood if I get some suitable off cuts.

I've tried to post more video on Youtube (Del Cat is the channel name)

Someone posted a Youtube link to a Lego Archer Automaton which is very good, it’s based on an experimental one I made some years back. The Lego one is much more presentable but uses my basic design/mechanism. I was gratified to see that the guy who made it acknowledged my design.

A search on Youtube should find it, as it’s worth a look.

It's funny how some little things stick in my mind from the year... seeing a newt in the garden pond was particularly satisfying as it's the first we've seen. (When we moved here about 25 years ago the pond was dried up and needed a re building with a decent rubber liner).

It's gone cold today, too cold to go into the garage, but I'll probably dig out the heater and get out there to finish off a scruffy billeted Yew bow I've been working on, then start on the Walnut or Elm.

Anyhow, lets hope that by the time the weather warms up again in the spring, the covid situation is calming down.

All the best to one and all.