Ah well, my calculations/estimates seem to be a bit too pessimistic, but better too strong than too weak! It's too stiff even after reducing the Ipe a little and rounding the belly. It was about 50# at 12" unbraced.

It was also trying to flip over sideways as it was rather thick compared to its width, also being unbraced and only pulling a few inches doesn't help.

I don't want to make the Ipe too thin, so I've carefully run it through the bandsaw down the middle of the thickest lamination and re-glues it. That takes about 1.5mm from the thickness.

Hopefully once it's finished I'll be able to work out some sort of fiddle factor for boo/Yew/Ipe.

Everything an amateur bowyer does to turn a log into a bow throughout the year. Making bows, longbows and primitive bows with all the tips, tricks and problems.

Saturday 24 August 2024

More Boo Yew Ipe

Thursday 22 August 2024

Boo Yew Ipe Flight ELB draw weight estimation

So I'm tillering it as Boo Yew stave and trying to estimate how the extra 4.5 mm of Ipe will increase the draw weight. Just for ease of calculation I'm assuming the Ipe will be the same as the Yew (it is stronger in compression, but I'm just trying to get an estimate.

Currently the bow is 40# @ 17.5" which correlates to 61.7 @ 27" draw (short draw flight bow).

Mid limb thickness is 16mm. 16 cubed is 4096 (stiffness being proportional to the cube of the thickness)

If I add 4.5mm to the thickness this gives 20.5 which when cubed is 8615.

8615/4096 = 2.1 so adding 4.5mm would give 2.1 times the draw weight! 129#

Hmm, looks like I need to take more off the belly before glue up.

Trying to calculate an appropriate draw weight and length without the Ipe to give the desired final result with the Ipe is beyond me, so it's down to the old successive approximation. Keep doing a bit and re-calculating.

BTW. Target draw weight is somewhere between 60 and 80#, so I have some margin to play with.

I've currently got it drawing 19" at 35# with a 15mm thickness mid limb, which is giving a finished estimate of 101# . Still a bit high, if I can get the estimate down to below 90, I think I'll go for glue up.

Tuesday 21 May 2024

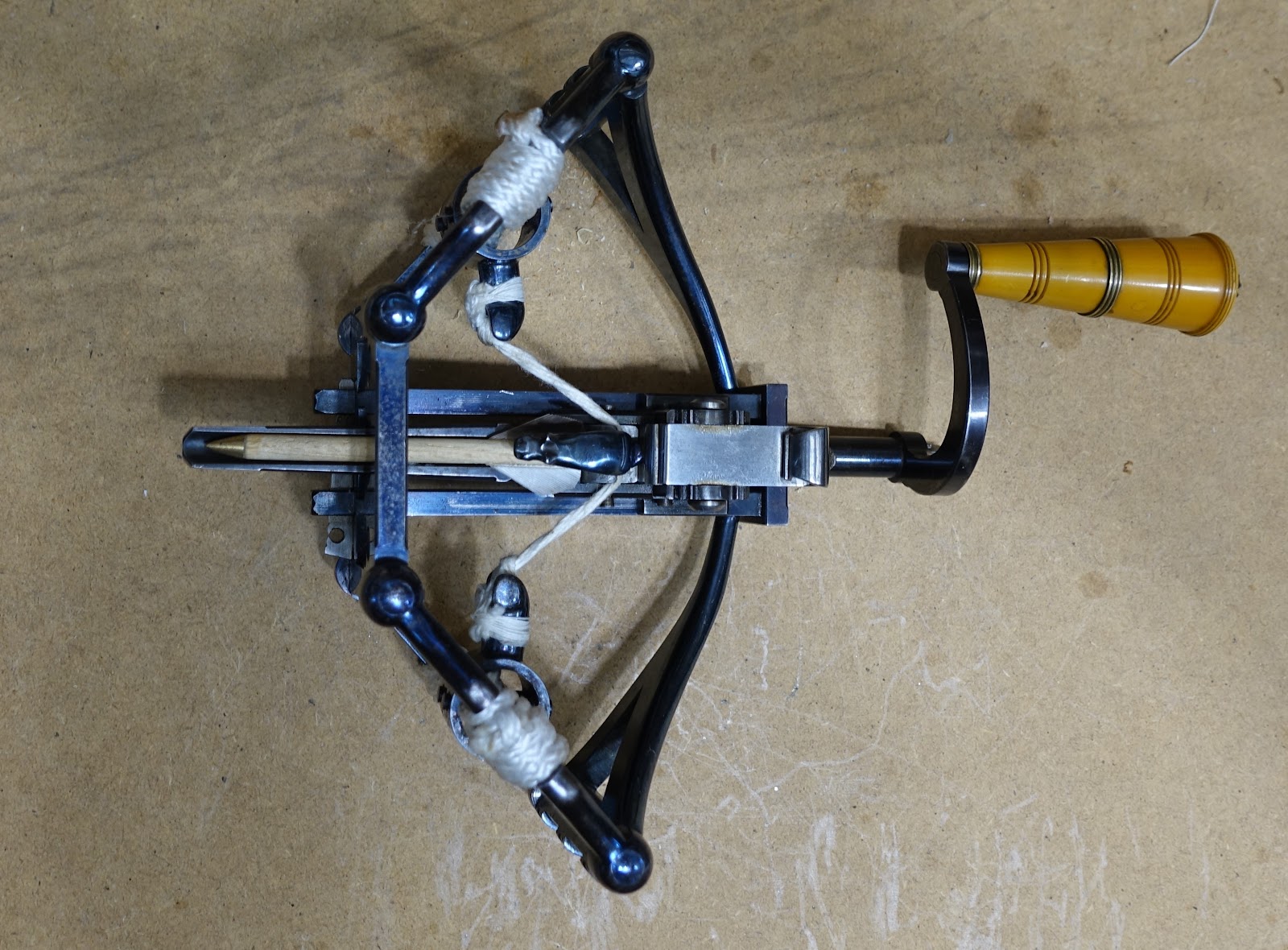

Test Shot with Miniature Ballista

It was a pig to bind the string onto the stubby arms of the ballista, and having tied one end on, that arm had to be held under tension by wedging it against the frame with a screw driver. I managed to get it done and it works! I'm using temporary skeins of braided nylon cord, as the cat gut was too powerful.

Getting it working has revealed several design flaws, and I firmly believe that is is an apprentice piece* to demonstrate the metal working skills of it's maker, rather than being an exercise in building a working miniature ballista.

* Possibly by a gunmaker or crossbow maker.

https://www.youtube.com/watch?v=Jqg6Qp7p2ok

Thursday 16 May 2024

Miniature Ballista

I bought this from a "Fine English Sporting Guns and Rifles" auction. The attached label doesn't give much info, and the string is broken. I'm hoping to figure out how it works and get it going. It should provide many hours of fun. The trigger mechanism has virtually no wear on it, so I'm assuming it was made for the fun of it or as a demonstration of the workers skill. Probably Victorian?

The arms that the string attaches to look rather short to me and there is no obvious way to pre tension the skeins of sinew. The 'wings' can fold back or forth and this may provide a way of stringing and pre tensioning.

Here's a transcript of the info that came with it written on 2 tiny labels.

Text broken int 4 sections corresponding to the 4 sides

sides of the two labels. My comments in italics

Ballista/

Steel with folding “wings” :-

Origin and age not known, but animal-like sight looks oriental as does

decoration:-

Fitted with 14th century European pattern revolving nut; but the

groove in the stock is flat, not curved as in medieval bows to cut down

friction; if the bolt was flighted it would have to be less than ¾” across to

clear the columns in the central window (to be in scale the flights would be

about 5/8”

----

across, with 3 flights) ; Winding handle may be in Ivory but more likely in

Ivorine an early plastic;

Ones first impression is that it is French, the steel ‘stem of the handle’? is

half-heart shaped, elegant and ‘resolved’? ; Fixing wedge is oddly short and

undecorated; See ballistas on stands in Payne-Gallwey’s book “The Crossbow”;

bought from Terry Sovine (French name?) (address given but not shown here).

----

David Martin wonders whether the bow has been put on back to front; there are

two holes in the side of the frame towards the back which may be to fix the

crossbow to a stand. (I disagree); when strung the string slopes

downward from the centre; the screw thread on the screw holding the trigger

spring is approximately

----

1BA and the thread on the animal-like sight is 2BA- both are a bit sloppy so I

have locked them with Araldite; the barrel wobbles up and down a little; the

sight centres ones aim but is no help for trajectory; there are file marks

inside the outer wings and the centre ‘window’; catgut loose on right hand

claw.

Friday 5 April 2024

English Yew Primitive

This is my first successful bow of the year, 50# @28"

(an earlier Wych Elm primitive exploded after about a dozen shots! I shall be doing a "repair" and destruction test later, just to see how well linen binding supports a break).

The Yew was local to me, it had been felled by the council following some storm damage, and just left to rot.

The bow has some nice character is 66" from nock to nock, and the limbs are 2" wide at their widest.

Playlist for the entire build here:-

https://www.youtube.com/playlist?list=PLBz2tD9476KSe_bzPG5ZZRhW5_lEGsUWq

Saturday 13 January 2024

Dear Diary a log and repairs

I've been pressing on with the Hickory flight bow rework despite multiple failures, as it seems to be providing opportunity for experimentation and learning for relatively little expenditure of time and effort.

Meanwhile one of the guys from our 'club' (a bunch of blokes who lob arrows around a field between sampling flavoured rum and eating cakes) brought me a 5' length of Yew log and a bow which I'd made him a few years ago, but was now too heavy. He wanted the 70# boo, Yew, Lemonwood taken down to 50#).

I then got contacted via facebook about a bow repair, it turned out to be a Ravenbeak bow (Boo,Yew,Yew) that I'd repaired before to patch a belly chrysal. It looks like the chrysal has returned and presumably the patch needs to be thicker and more extensive (Maybe there is a weak area in the core ?)

Mean while I've decided to cut the yew log into 4' billets as the thin end was a bit scruffy. The log is still very fresh and green and my 3tip alternate set bandsaw blade was worn out. I started to sharpen it, but soon gave up and ordered two new blades (from Just Bandsaw Blades).

So while I'm waiting for the bandsaw blades I need to have a good tidy up. Th bloke will be bringing the Ravenbeak repair over on Wednesday, so that will be an excuse to have a go with the Chinese repeater etc.